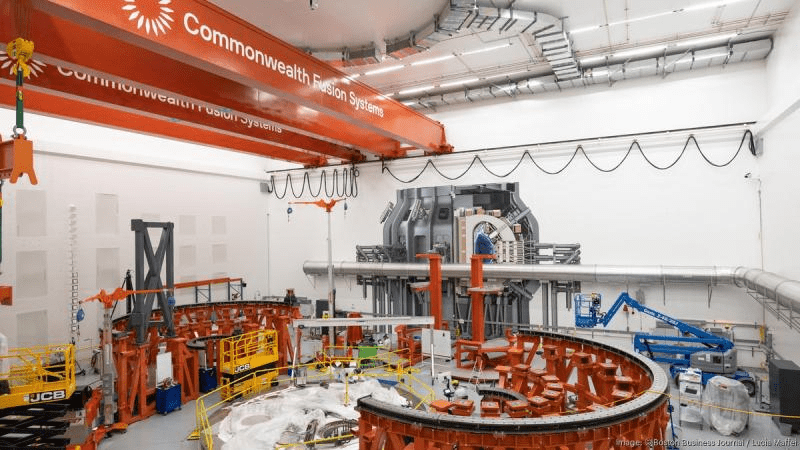

Commonwealth Fusion Systems Sparc reactor magnet marks a turning point

The Commonwealth Fusion Systems Sparc reactor magnet has crossed a critical engineering milestone. The company confirmed the installation of the first magnet inside its Sparc fusion reactor, a demonstration system targeted for activation next year. This step moves fusion power closer to operational reality after decades of delay.

This initial magnet is the first of eighteen required to complete the reactor. Once fully installed, the magnets will form a doughnut-shaped configuration. That structure is designed to confine and compress superheated plasma. If performance holds, the plasma will release more energy than it consumes during heating and compression.

The Commonwealth Fusion Systems Sparc reactor magnet installation signals progress toward a long-standing industry goal. Fusion power developers are racing to deliver the first electrons to the grid in the early 2030s. Success would introduce a clean energy source that resembles a traditional power plant in scale and operation.

Magnet engineering sets the foundation for reactor performance

Each magnet in the Sparc system is engineered for extreme performance. When installed, the D-shaped magnets will stand vertically on a stainless steel cryostat measuring twenty-four feet across and weighing seventy-five tons. This cryostat was set in place earlier, preparing the physical base for magnet installation.

Each unit weighs approximately twenty-four tons. Together, they can generate a magnetic field of twenty tesla. This field strength is roughly thirteen times stronger than a typical MRI machine. Achieving this output requires cooling the magnets to minus two hundred fifty-three degrees Celsius. At that temperature, they can safely conduct more than thirty thousand amps of current.

Inside the magnetic ring, plasma temperatures will exceed one hundred million degrees Celsius. The Commonwealth Fusion Systems Sparc reactor magnet is therefore central to both containment and stability. Without this capability, sustained fusion reactions would not be possible.

Digital twins accelerate learning and operational readiness

To reduce uncertainty before powering on Sparc, the company is building a comprehensive digital twin of the reactor. This effort combines design and manufacturing software with advanced simulation libraries. The goal is to move beyond isolated simulations and create a live, parallel system.

With this approach, experiments and parameter changes can be tested digitally before being applied to the physical reactor. The digital twin will operate alongside the machine itself. Continuous comparison between simulation and reality is expected to speed learning and refinement.

This integration reflects a broader strategy. The Commonwealth Fusion Systems Sparc reactor magnet is not only a hardware achievement. It is part of a data-driven development model that blends physical engineering with ongoing computational feedback.

For organizations navigating complex technology transitions, this approach offers a useful parallel. Many enterprises now combine physical assets with digital replicas to improve speed and reduce risk. Explore the services of Uttkrist. Our services are global in nature and highly enabling for businesses of all types. Drop an inquiry in your suitable category at https://uttkrist.com/explore/.

Cost, capital, and urgency define the path ahead

Building Sparc has required significant investment. The company has raised nearly three billion dollars to date. Its next step, a commercial-scale power plant named Arc, is expected to require several additional billions.

Despite the cost, urgency remains high. Management believes that improved machine learning tools and more precise digital representations can shorten timelines. Faster learning cycles could help fusion reach the grid sooner.

The Commonwealth Fusion Systems Sparc reactor magnet therefore represents more than a component installation. It reflects a convergence of advanced materials, extreme engineering, and digital systems. Together, these elements aim to convert fusion from promise into practice.

As fusion development accelerates, what lessons can other capital-intensive industries take from this blend of hardware precision and continuous digital learning?

Explore Business Solutions from Uttkrist and our Partners’, https://uttkrist.com/explore

Also explore language and workforce enablement solutions at https://qlango.com/